Author:Zhongan-ECO Comefrom: Date:2022/2/20 11:02:37

Improper tire disposal is not only harmful to the environment; it is also an incredible waste of a highly useful resource. Recycled tire material is now being used in everything from garden pavers to playground flooring. Here are a handful of the amazing uses for End of Life Tyres:

Anywhere gravel is used, chances are that tire chips can be used instead. Applications include: sub-layers for roadways, aggregate for drainage ditches, and highway embankment backfill. Tire chips can limit frost penetration, when used under roads in cold climates. They are nearly three times as light as gravel, which on its own can produce incredible savings in labor, equipment costs and time. Tire chips are used under light rail tracks that run adjacent to homes and businesses, to reduce vibration and noise mitigation from passing trains.

Crumb rubber is finely ground rubber produced from waste tires. Steel and tire cords are removed from discarded tires, and the remaining rubber is reduced to a granular consistency. Some applications for crumb rubber include: rubberized asphalt, playground flooring, welcome mats, anti-fatigue mats and vehicle mud guards.

Shredded or chipped tires can be used as both a liner and/or a cover for landfills. Tire chips can be used as a thermal insulation between primary and secondary landfill liners to reduce temperatures. They also provide a great alternative to coal or incinerator ash, since both are permeable. Finally, tire chips can be used as an efficient and cost-effective landscaping medium for landfills.

Tire chips can be shredded into a specific and uniform size, making them useful in a variety of ways. Another innovative use is filters in wastewater treatment and constructed wetlands. Because tires can be chipped to be more or less porous than organic compounds, rocks and other material, they often serve as a much better filter media.

Yet another innovative use for recycled tires is rubber mulch. Not only does it retain its appearance over time, it doesn’t float away during rainstorms, nor will it rot the way wood mulch will. Unlike wood mulch, tire chips don’t attract termites and other wood-boring pests.

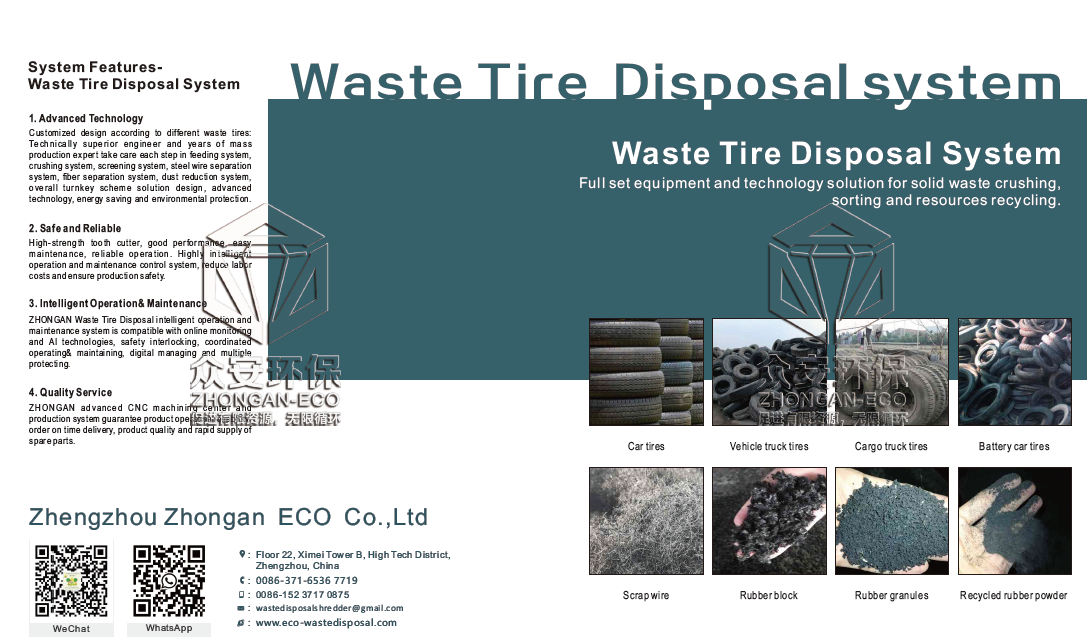

Zhongan-ECO as the trendsetter in waste tire disposal technology in China, our experienced engineer team provides comprehesive waste tire disposal solution and even think ahead according to customer's actual demand and scrap tire real situation. Almost 20 years experience of waste disposal technology and collecting knowledge of process, we know what are the major problems during waste tire disposal and give our professional suggestion to you.

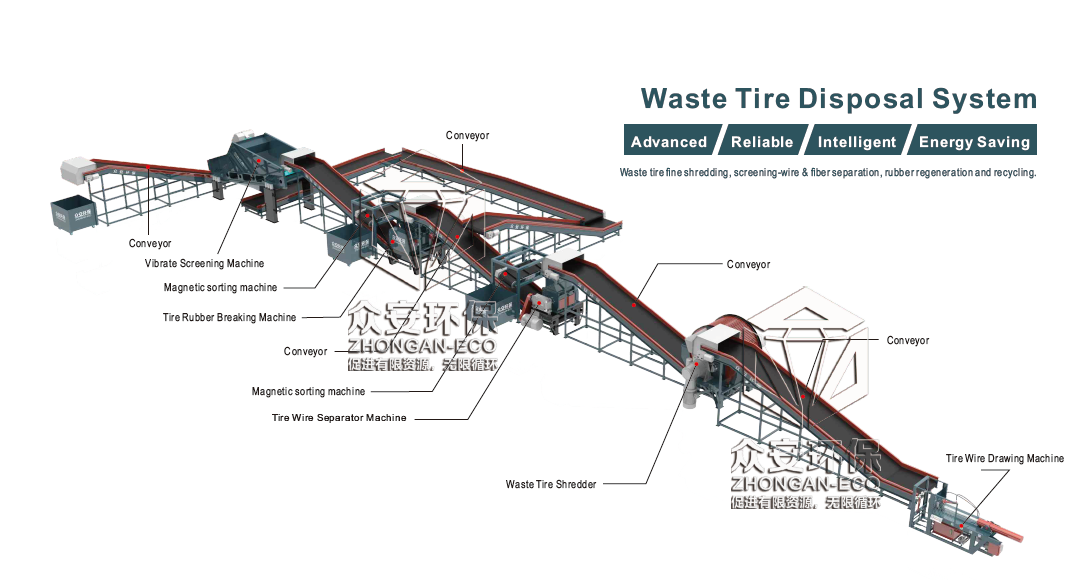

Waste tires are first drawn off the sidewall steel wires by hydraulic wire drawing machine, then sent to the tire shredder by conveyor for crushing & screening to produce reasonable size rubber blocks. The next step is wire separator to separate thin wires in the crushed rubber block , subsequently, the vibrating conveyor equipment performs vibratory screening, then the fiber separator and magnetic separator separate the fiber and steel wire from the shredded rubber powder, and finally the product under the sieve is the finished fine rubber particle & rubber powder. The entire waste tire disposal system is enclosed working in conveying, negative pressure dust reduction, energy saving and environmental protection.

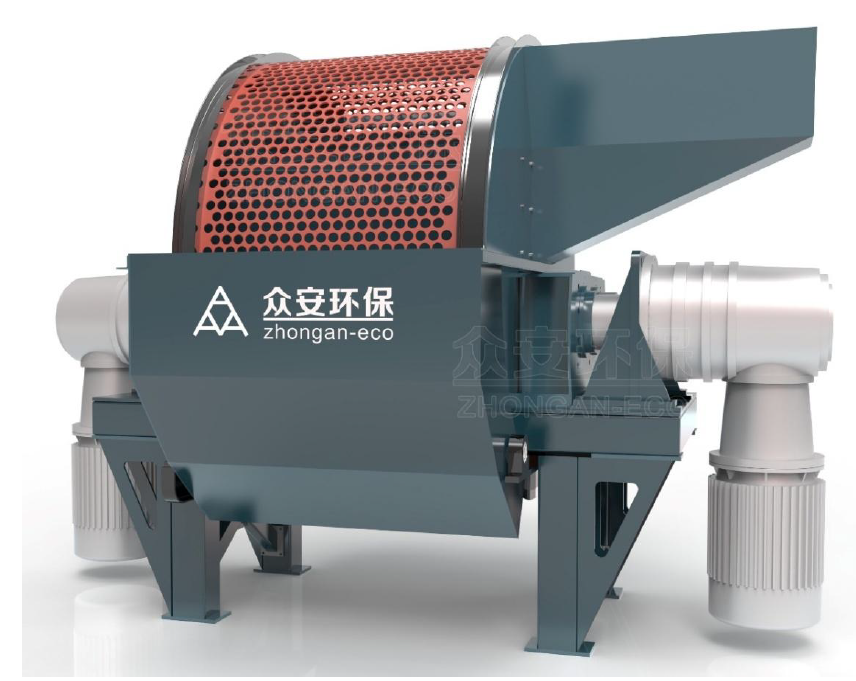

Zhongan double shafts tyre shredder updated from European technology innovative design, shredds scrap tyre to a smaller particle size through the comprehensive principle of shearing, crushing and shredding. Waste Tyre Shredder is driven by the power system to drive the knife shaft and make the active cutter rotor rotate at a low speed. The cutters tear and shear each other to shred the tyre, and meanwhile, integrated drum screen ensures the consistency of discharged crushed size. The Waste Tyre Shredder consists of knife box, motor, reducer, integrated rolling screen, frame, intelligent operation and maintenance control system, etc.

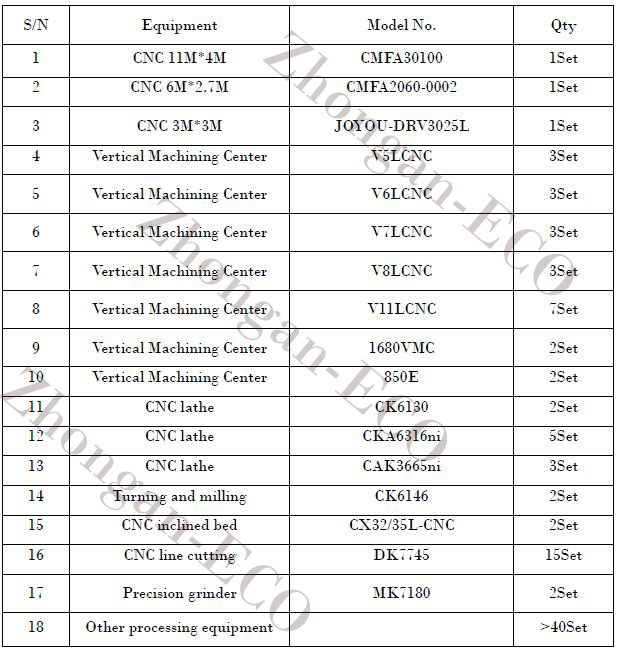

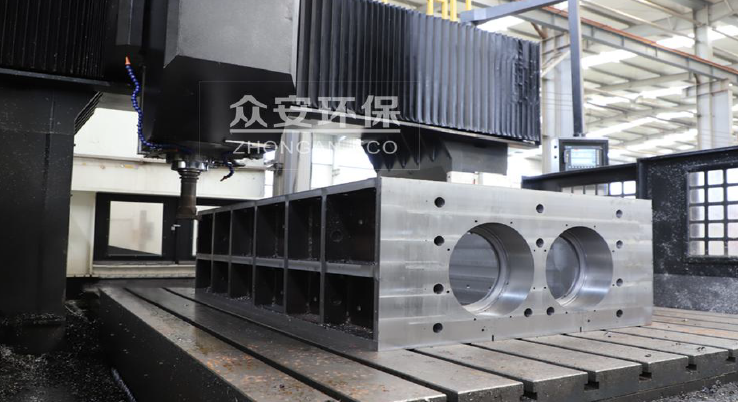

The cutter chamber is processed by large CNC machining center at one time, high accuracy machining ensures the bearing seat good concentricity, stable and reliable. Modular design, simple structure and convenient maintenance.

Main spindle material: forged and tempered with 42CrMo

Advantages: After quenching and tempering process, it is refined and processed by high-precision large-scale CNC equipment, good strength, strong impact resistance and long service life. Our large machining center guarantees the machining accuracy of the spindle.

Finish by CNC grinding machine and wire cutting ensures high accuracy machining. The knife cutter has good wear resistance and moderate tenacity. Zhongan has complete processing equipment and better quality control. Cutters can be assembled only after it has passed the ultrasonic inspection, hardness test, dimensions inspection and other inspections.

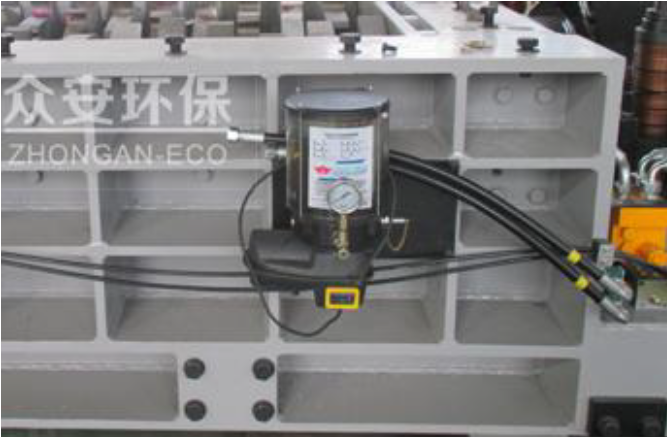

Automatic lubricating device and control module ensures the oil in the bearing is always in a sufficient state, prevent the bearing from wearing and lead to the shredder working, and ensures the long-term operation of the equipment. Compared with manual oiling, it greatly saves maintenance costs and avoids equipment failure caused by untimely maintenance, the reliability of the equipment is obviously improved.

The double-stacked self-locking washer is used to prevent the bolt from loosening. This washer has a unique wedge-type structure, and the double-sided embossing bites and moves, improved the traditional anti-loosening method that relies on friction.

The intelligent monitoring system is composed of intelligent data acquisition system, intelligent automatic control system and intelligent crushing system cloud service platform, including one-key start-stop, condition monitoring, data analysis, collaborative optimization, fault diagnosis, alarm linkage and other functions. Adding a variety of intelligent multi-sensing devices to the key equipment such as feeding, crushing and conveying of the entire production line, it realized equipment centralized management, fault automatic response, maintenance and after-sales remote control, the cost of equipment operation and maintenance management are reduced.

Intelligent centralized control mainly includes the following intelligent functions:

Siemens PLC + touch screen control, with automatic protection for overvoltage, overload, over-current, short circuit.

Monitoring key parts of hydraulic pressure, lubrication, bearings, motors, and reducers, multiple protection and intelligent.

In case of un-shredable objects, it will automatically reverse, it will also automatically alarm and stop when the set number of reverses is reached.

Crushing production line control system software protection technology, production line intelligent linkage to ensure safe operation.

Shredder operation self-diagnosis system, operation and maintenance detection system software protection technology.

Real-time monitoring of equipment operating status, accumulated historical data can be used for retrospective analysis and process optimization.

Shredder intelligent monitoring system software protection technology.