Author:Zhongan-ECO Comefrom:Andre Niu Date:2022/9/4 0:43:24

Guide:

MSW contains a lot of high calorific value components, if the waste is directly incinerated or landfilled, the calorific value will not be effectively utilized. Coupling power generation and co-processing through existing fire power plants, thermal power plants and cement plants, combined with RDF/SRF pelletizing technology, it does not require landfill or large investment in the construction of waste incineration power plants to realize MSW harmless, reduction, resource utilization, energy utilization.

1. The organic matter in the garbage is extremely perishable, and it is difficult to transport or store;

2. Garbage has the characteristics of large fluctuation in composition and calorific value, high moisture and ash content, which is easy to cause unstable combustion;

3. Garbage often contains plastics, table salt and other chlorine-containing compounds. When heated at high temperature, corrosive hydrogen chloride gas will be generated. The discharge of hydrogen chloride can form acid rain, and can corrode metal equipment in the furnace; due to the existence of chlorine-containing compounds, it is also possible produce highly toxic and harmful substances - dioxins, which will cause more serious harm to human health;

4. The ash discharged after garbage incineration usually contains harmful metals, such as mercury, lead, etc. If not handled properly, it will also cause secondary pollution to the environment.

Based on the above situation, MSW needs to be pretreated before it can be used. The municipal solid waste is effectively pretreated and shaped before entering the furnace, and then make it into RDF/SRF pellets provides a new idea for solving the above problems. Now municipal solid waste, general industrial solid Waste, papermaking waste, washing plant waste, scrap steel mill waste, textile waste, leather waste, rag waste, waste clothing and other materials can be used for RDF/SRF pellets production.

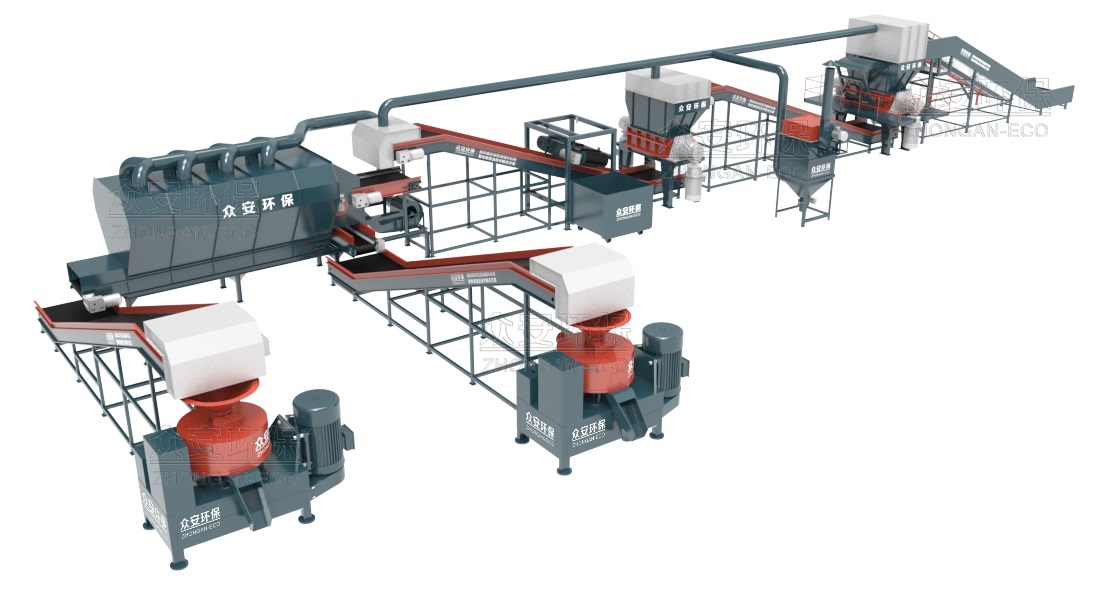

After the municipal solid waste is shredded by the double-shaft shredder and the fine shredder, it enters the RDF/SRF pelletizing machine and is extruded into RDF/SRF high-density particles, which are used as fuel for the power plant to generate electricity, realize resource reuse. The waste-derived fuel RDF/SRF treated by the RDF production line has the significant advantages of high calorific value, stable combustion conditions, RDF-5 volatile more than 75% and moisture less than 20%. Can be used in large-scale circulating fluidized bed boilers in huge quality or combined combustion and coupled power generation, a large number of coal fuels can be save a lot for enterprises, meet the standard requirements. It also ensures the safe, stable and continuous operation of the power plant, and meanwhile, the emission meets the standard requirements.

1) Adopt electromechanical hydraulic integration technology, mature structure and stable operation;

2) The mold is independent in single piece , convenient, fast and easy to replace;

3) Automatic lubrication and electro-hydraulic lubrication device, convenient for maintenance;

4) Automatic reversal function, it can reverse runing if overloaded.

The RDF/SRF pelletizing machine is composed of machine base, protective cover, feeding port, pressing wheel, flat die and a discharging port.

First crush the material to 30-60mm and make moisture in the range of 15%-25%, the material is fed into the feeding port of the pelletizer through the feeding conveyor, the material is evenly dispersed into working area between the pressing wheel and the flat die of the pelletizing machine. The main shaft drives the pressing wheel rotating, and the material is forced to be extruded from the flat die into pellets and falls from the discharge port.

RDF/SRF pelletizing technology has brought vitality to waste energy and has become a new growth point in the field of waste utilization. It is widely used in coal-fired power plants, thermal power plants, waste incineration power plants, biopower plants, cement plants, etc. Effectively accelerating the transformation of electricity upgrade, gradually realize green and low-carbon power production, and contribute to the world energy transformation.